Are you talking about this stuff - I have that set and I'm a little afraid of it.

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Anyone built with intense quilt bubinga? http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=8760 |

Page 1 of 1 |

| Author: | Todd Rose [ Mon Oct 09, 2006 7:08 am ] |

| Post subject: | |

I just received a set of some of that intensely figured quilted bubinga we've probably all seen. The sides arrived broken, snapped right in the middle. Looking at the break, as well as looking at the grain on the edge of the boards, I can see that the grain zig-zags extremely -- much moreso than your average curly-figured wood (I've just looked at the edges of several sets of various curly woods I have in my stock to compare). It's no wonder that the sides snapped, with the grain running nearly perpendicular to the surface in many places. It makes me think it must be extremely difficult to bend this wood without breaking it. Have any of you used this stuff and found that to be the case? Or have you found that it actually bends reasonably readily? Your input would be helpful to me in deciding whether I want to order a replacement set or just get my money back. I'd also be interested in hearing any observations about the sound of guitars built with this stuff. It's amazingly beautiful, but with what seems to be virtually no longitudinal grain integrity, I wonder if it can make a good sounding guitar. The tap tone sure isn't much to speak of. Thanks! |

|

| Author: | Don Williams [ Mon Oct 09, 2006 7:25 am ] |

| Post subject: | |

The more intense the curl or quilt, the more extreme the localized runout... There's another type of "quilt" in bubinga, which is a really tight figure. Sergei DeJonge had a couple guitars with that wood in the Newport show. One of them had a laminated top of the stuff. Perhaps the reason for the lamination was due to that very issue. Great looking wood though, and to some folks the sound is very good too. I've heard some great tap tone coming from Bubinga. I guess it depends on the board. |

|

| Author: | Steve Saville [ Mon Oct 09, 2006 7:36 am ] |

| Post subject: | |

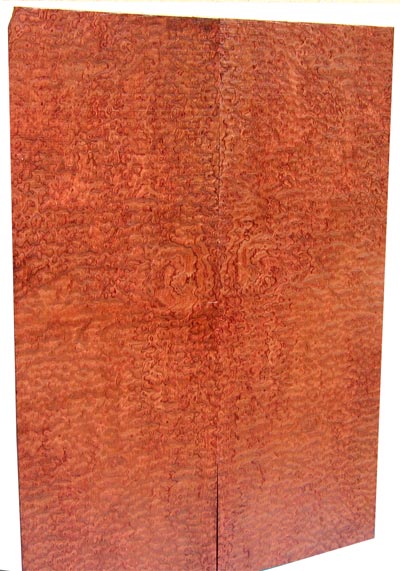

Are you talking about this stuff - I have that set and I'm a little afraid of it.

|

|

| Author: | JJ Donohue [ Mon Oct 09, 2006 8:25 am ] |

| Post subject: | |

I just finished an OLF-SJ made from Waterfall Bubinga from the Zootman. It is the most hypnotic wood I've ever seen. Tap tone was decent and the resonance, tone and volume of the finished instrument sounds better than anything I've made to date. I was expecting to have a difficult time bending the sides but was pleasantly surprised at how well it went. One area that requires a LOT of attention is sanding and scraping the sides level after bending. Because of the extremely high figure, it gets lots of peaks and valleys that need to be flattened before binding and finishing. I can't begin to tell you the number of hours I spent getting it smooth. In general, I was quite pleased with the Bubinga. Fotunately I have a second set I'm sitting on for another day. |

|

| Author: | harmonist34 [ Mon Oct 09, 2006 9:29 am ] |

| Post subject: | |

Trevor Kronbauer's building a guitar for a client of mine with some of the crazy stuff. Bending went okay but there was one spot where the quilt didn't want to bend along with the sides and split off. I believe he was able to coax it into position and glue it...hopefully there will be no long-term issues with the wood. Certainly is striking! Andrew  |

|

| Author: | GregG [ Mon Oct 09, 2006 9:42 am ] |

| Post subject: | |

I haven't built with this Bubinga yet, but I sure do like the looks of it.....wonder how difficult it is going to be, it weighs a ton!

Greg |

|

| Author: | Don Williams [ Mon Oct 09, 2006 10:11 am ] |

| Post subject: | |

This picture from LMI is probably more like what Todd is refering to...:

The waterfall stuff is reasonably stable. Several people have built with it with fine results. |

|

| Author: | Chris -LMI [ Mon Oct 09, 2006 10:42 am ] |

| Post subject: | |

Todd, We've bent the stuff we are selling, as have numerous customers, without any complaints. Not that bending figured wood is ever a piece of cake... -Chris, LMI |

|

| Author: | Joe Beaver [ Mon Oct 09, 2006 2:29 pm ] |

| Post subject: | |

[QUOTE=Chris -LMI] Todd, We've bent the stuff we are selling, as have numerous customers, without any complaints. Not that bending figured wood is ever a piece of cake... -Chris, LMI[/QUOTE] Chris, I figure you guys are some of the most experienced around bending figured wood. How do you bend the highly figured bubinga and other woods? Bend it dry? Light sprit? How hot do you bend at? Thanks for any answers you can give!!! |

|

| Author: | Todd Rose [ Mon Oct 09, 2006 10:44 pm ] |

| Post subject: | |

The stuff that Andrew shows in his post looks almost exactly like what I got. Chris, thanks for your input. I'll take your word for it. Maybe if the guys I got this from don't want me to return the broken sides, I'll try bending them and see what happens. It hardly seems possible that this stuff could be bent without breaking, but if others have done it, than it can be done. |

|

| Author: | Larry Davis [ Tue Oct 10, 2006 12:06 am ] |

| Post subject: | |

Todd, if the sides broke in shipment it's probably because they wern't packed properly and any other wood grain orientation is secondary to the cause. Bending highly figured wood is always a crap shoot given that we fully understand what makes wood "figured".....undulating or wavy grain in some grain orientation which naturally causes run out and end grain on the surface in some cases. This is a given expectation when buying figured woods we must take into account. True quilted wood will be cut on the tangent (or some degree of tangent) to emphasize figure which makes it weaker yet. No better example than quilted maple thru a planer and hearing "pings" as the figure "bubbles" chip out and off. Just my .02. |

|

| Author: | Todd Rose [ Tue Oct 10, 2006 1:22 am ] |

| Post subject: | |

Larry, gotcha. And you're right, I think packaging was an issue in this case. I'm fully cognizant of what you're saying about figured wood. I've just never seen a guitar set where the runout due to the figure is as extreme as on this stuff. "Runout" is an understatement. The undulation is so extreme that in many places, the grain runs directly across the board from one surface to the other. I don't see that on any of the other highly figured woods I have in my stock. These guys may get away with the packaging they did on most of their woods, but with grain like this, this stuff has just got to be a lot more fragile. I'm still interested to hear anyone's experience with the sound of guitars built with this crazy bubinga. I've heard a lot of good things about bubinga (I haven't built with it yet myself), but this gonzo-grained stuff surely has very different acoustic properties. Greg and Steve, do your sets have a nice ringing tap? I would think they would. That's a more normal figure that I wouldn't expect to have a big effect on the acoustic properties. This stuff is something entirely different. |

|

| Author: | Larry Davis [ Tue Oct 10, 2006 1:29 am ] |

| Post subject: | |

Todd, adding to the run out might be it's not sawn parallel to the log pith? This would be cross grain added to the undulating grain...just a thought...but your description is unusually severe grain for quilted figures. |

|

| Author: | JBreault [ Tue Oct 10, 2006 2:14 am ] |

| Post subject: | |

Hopefully Al Caruth will chime in here. Speaking to him on Sunday, he was recounting how he bent a side with a crack in it by backing the cracked area with paper and superglueing it there. The craked area bent fine with the rest of the wood. He also noted that by backing the wood with paper and superglue, he was able to bend a real tight cutaway. So, perhaps if you are really afraid of bending highly figured wood, use Al's paper and superglue method. There will be lots of cleanup in the end, but I believe the insurance worth it. |

|

| Author: | CecilJ [ Tue Oct 10, 2006 2:16 am ] |

| Post subject: | |

This is a 12-string built with bubinga from LMI, bearclaw sitka top, and maple neck. It is difficult to compare because I don't have my Gibson 12 around. It sounds a little "tight" right now but I expect it will "open up" with more play. I have only had it a month. 12 strings are always difficult for me to compare with 6 strings because they have so many high note strings. My friend said bending the sides was difficult and comared it to some quilted maple he did for me.

|

|

| Author: | Todd Rose [ Wed Oct 11, 2006 1:47 am ] |

| Post subject: | |

Thanks, Joe and Cecil, for your input. BTW, I got a pm from an experienced builder (who shall remain nameless since he chose to pm me) who has built a couple of guitars with this dazzling crazy-grained bubinga (he got his from LMI, which I did not, but it looks like the same stuff). He said they sound very good, like "typical rosewood" guitars. He also said bending was fairly easy. So, I guess there's really no reason to shy away from this stuff. |

|

| Author: | Steve Saville [ Wed Oct 11, 2006 3:07 am ] |

| Post subject: | |

I just finished a bubinga guitar. It had bubinga back, sides, fretboard, headstock overlay and bridge. It was easy to cut and bend, but very hard to sand. For thickness sanding, make sure you take light cuts and have the feed very fast. If you go slow, you will probably burn it. I'm a big fan of bubinga. I think it sounds great. I own 2 more sets that I look forward to building with.

|

|

| Author: | MSpencer [ Wed Oct 11, 2006 7:48 am ] |

| Post subject: | |

GregG, your Bubinga will bend pretty well, mostly straight grain unlike the crazy waterfall grain lines. I have done 3 Bubinga guitars and found after having some problems with #1 bending the sides that if I took it down to .75 all went well. I spritz well, wrap in foil and bend at 290-300. Don't rush or force the bend, make sure the wood gives to the bend. I had trouble trying anything thicker or cooler. The Waterfall scares me a little SteveS, I like your set, I think it will do fine, the grain patterns don't seem to be as tight and swirly as the photos from Don and what Todd seems to have. Mike Good Luck, |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|